Metal Finishes

Post-machining treatments for your CNC machined parts.

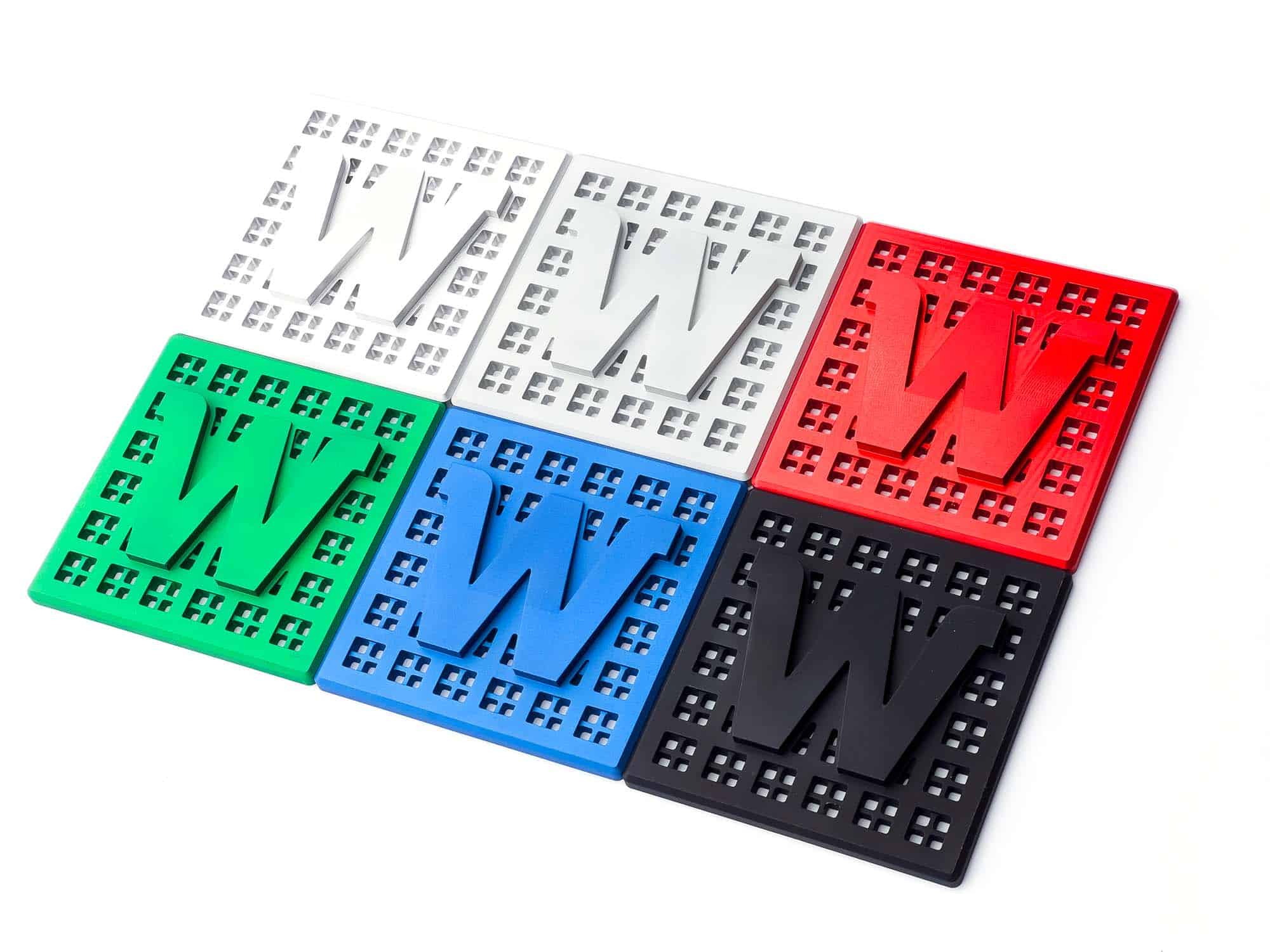

MATTE ANODISING

Anodising is available for aluminium alloys and fulfils both the role of changing the color of the object, but above all of protecting it by creating a protective shield against chemical attacks to oxidation. It has a thickness of 10 microns for interiors and 20 microns for exteriors.

Anodising is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. The process is called anodising because the part to be treated constitutes the anodic electrode of an electrolytic cell. Anodising increases corrosion and wear resistance and provides better adhesion to primers and glues than bare metal. In addition, the oxide layer created is an excellent electrical insulator, reducing the conductivity of the metal and aiding the dissipation of electrostatic charges, thus decreasing the risk of electrostatic discharge (ESD) in sensitive environments.

By choosing matte anodising, parts are shot-peened before the chemical process. This, from an aesthetic point of view, allows any tool marks to be hidden.

Available for Aluminium 6082 and 7075

GLOSS ANODISING

Anodising is available for aluminium alloys and fulfils both the role of changing the color of the object, but most of all of protecting it by creating a protective shield against chemical attacks to oxidation. It has a thickness of 10 microns for interiors and 20 microns for exteriors.

Anodising is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. The process is called anodising because the part to be treated constitutes the anodic electrode of an electrolytic cell. Anodising increases corrosion and wear resistance and provides better adhesion to primers and glues than bare metal. In addition, the oxide layer created is an excellent electrical insulator, reducing the conductivity of the metal and aiding the dissipation of electrostatic charges, thus decreasing the risk of electrostatic discharge (ESD) in sensitive environments.

If glossy anodising is chosen, some tool marks may be visible on the finished component.

Available for Aluminium 6082 and 7075

LANCET SHOT PEENING

Metal materials produced by CNC machining can be shot peened to even out the surface, removing tool marks and improving the fatigue performance of the parts. With this finish, sharp edges may be slightly bevelled as a result of surface polishing.

Available for all Metals

QUOTE IN 1 SECOND WITHOUT COMMITMENT

DON'T WAIT: UPLOAD YOUR 3D FILE AND GET A QUOTE FOR YOUR PARTS NOW!

Upload your 3D file to get one step closer to manufacturing your parts.

free instant quote