| PETG ESD | |

|---|---|

| Properties | |

| Tensile breaking load | 36,1 MPa |

| Modulus of elasticity | 1,986 GPa |

| Elongation at break | 7,3 % |

| HDT 0.45 MPa | 76 °C |

| Density | 1,24 g/cm^3 |

| Features | |

| Price range | € € € € € |

| Lead time | <3 days |

| Quote | |

ESD Materials

ESD Protection, Resilience, and Innovation: Explore Our Advanced Range of Materials for Safe and High-Performance Solutions.

OUR 3D PRINTED ESD MATERIALS

Compare the properties

QUOTE IN 1 SECOND WITHOUT COMMITMENT

turn your 3D projects into reality

Upload your 3D file to get closer to the production of your parts.

free instant quoteWhat are ESD materials?

ESD materials are specifically designed to control, dissipate, and prevent the accumulation and discharge of static electricity. If unmanaged, static electricity can cause significant damage to sensitive electronic components, medical devices, computer equipment, and other delicate products. ESD materials act as protective barriers, absorbing or dispersing static energy to ensure it does not reach electronic components.

The increasing reliance on electronic technologies has made protecting electronic components from electrostatic discharges essential. ESD materials play a critical role across industries, including electronics, ATEX environments, and friction components. In the electronics sector, manufacturing integrated circuits, mobile devices, and computers requires highly controlled environments where electrostatic discharges are minimized to prevent defects and malfunctions. In ATEX environments, such as chemical and petrochemical plants, ESD materials are crucial to avoid sparks that could trigger explosions, safeguarding both facilities and workers. Additionally, in friction components like those in industrial machinery and mechanical devices, ESD materials help prevent static charge build-up that could interfere with functionality and longevity. In all these applications, ESD materials not only protect sensitive electronic devices but also contribute to the safety and operational efficiency of industrial infrastructures.

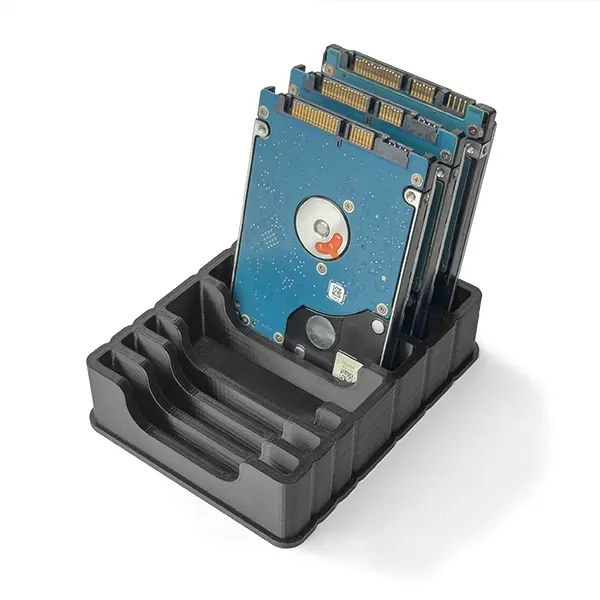

ESD materials find extensive use across various industries, primarily in electronics, ATEX environments, and friction components. In electronics, these materials are utilised for manufacturing specialised packaging, such as ESD bags and boxes, that protect devices during transport and storage, reducing the risk of damage from electrostatic discharges. In ATEX environments, ESD materials are used in flooring and work surfaces that dissipate static charges, preventing potentially hazardous sparks. Furthermore, they are integrated into anti-static clothing to ensure operators do not accumulate charges that could result in undesirable discharges.

For friction components, like those in industrial machinery, ESD materials enhance component resistance and durability, improving overall performance and preventing malfunctions caused by static electricity. ESD work surfaces provide safe environments for assembling and testing electronic devices, mitigating risks of unwanted discharges and ensuring product quality. Additionally, electronic components protected with integrated ESD materials benefit from enhanced reliability and longevity, ensuring devices operate efficiently without interruptions from static electricity issues.

The Advantages of Weerg for ESD Materials

Weerg is an innovative company in the 3D printing sector, renowned for its ability to deliver customised, high-quality solutions across a wide range of industries. When it comes to ESD materials, Weerg offers a host of unique advantages, making it a preferred choice for businesses seeking advanced and reliable solutions.

Advanced Customisation

One of Weerg’s primary strengths is its ability to provide highly customised solutions. Through advanced 3D printing technology, Weerg can produce bespoke ESD components tailored to clients’ exact specifications. This level of customisation is particularly valuable for businesses operating in high-tech sectors, where requirements can vary significantly from project to project.

High-Quality Materials

Weerg uses certified, high-quality materials for ESD applications. These materials not only meet the required standards for electrical dissipation and conductivity but also offer superior mechanical strength and durability. The quality of these materials ensures that ESD components perform effectively over time, maintaining their ability to protect electronic devices from electrostatic discharges.

Speed and Efficiency in Production

Weerg’s additive manufacturing technology significantly reduces production times compared to traditional methods. This means companies can quickly receive their ESD components, speeding up development cycles and reducing time-to-market. In fast-paced industries, where needs can change rapidly, this agility and flexibility are critical.

Cost Reduction

Weerg offers a cost-effective solution for producing ESD components by minimising material waste and optimising production processes. Additive manufacturing ensures that only the required components are created, reducing waste and lowering overall costs. Additionally, the ability to produce components on demand eliminates the need for large inventories, further cutting storage costs.

Innovation and Research & Development

Weerg continually invests in research and development to enhance its offerings and remain at the forefront of additive manufacturing technology. This commitment to innovation results in increasingly advanced ESD materials with improved electrical dissipation and conductivity properties. Businesses partnering with Weerg benefit from cutting-edge solutions, ensuring access to the most effective and state-of-the-art ESD materials on the market.

Technical Support and Consultancy

In addition to producing high-quality ESD components, Weerg provides comprehensive technical support and consultancy. Their team of experts collaborates closely with businesses to understand specific requirements and deliver tailored solutions that meet precise technical and operational needs. This level of support ensures that ESD components not only meet but exceed client expectations.

Case Study: Weerg and the Electronics Industry

To illustrate the advantages of Weerg in ESD materials, consider an example from the consumer electronics manufacturing sector. A company producing high-end smartphones requires ESD components to protect its integrated circuits during production and assembly. By collaborating with Weerg, the company receives customised ESD components that seamlessly integrate with their production processes.

Weerg’s rapid and tailored production capabilities allow the company to adapt ESD components to design modifications, ensuring optimal protection against electrostatic discharges. Additionally, the superior quality of ESD materials provided by Weerg guarantees that the components retain their protective properties over time, reducing malfunctions and enhancing the overall durability of finished products.