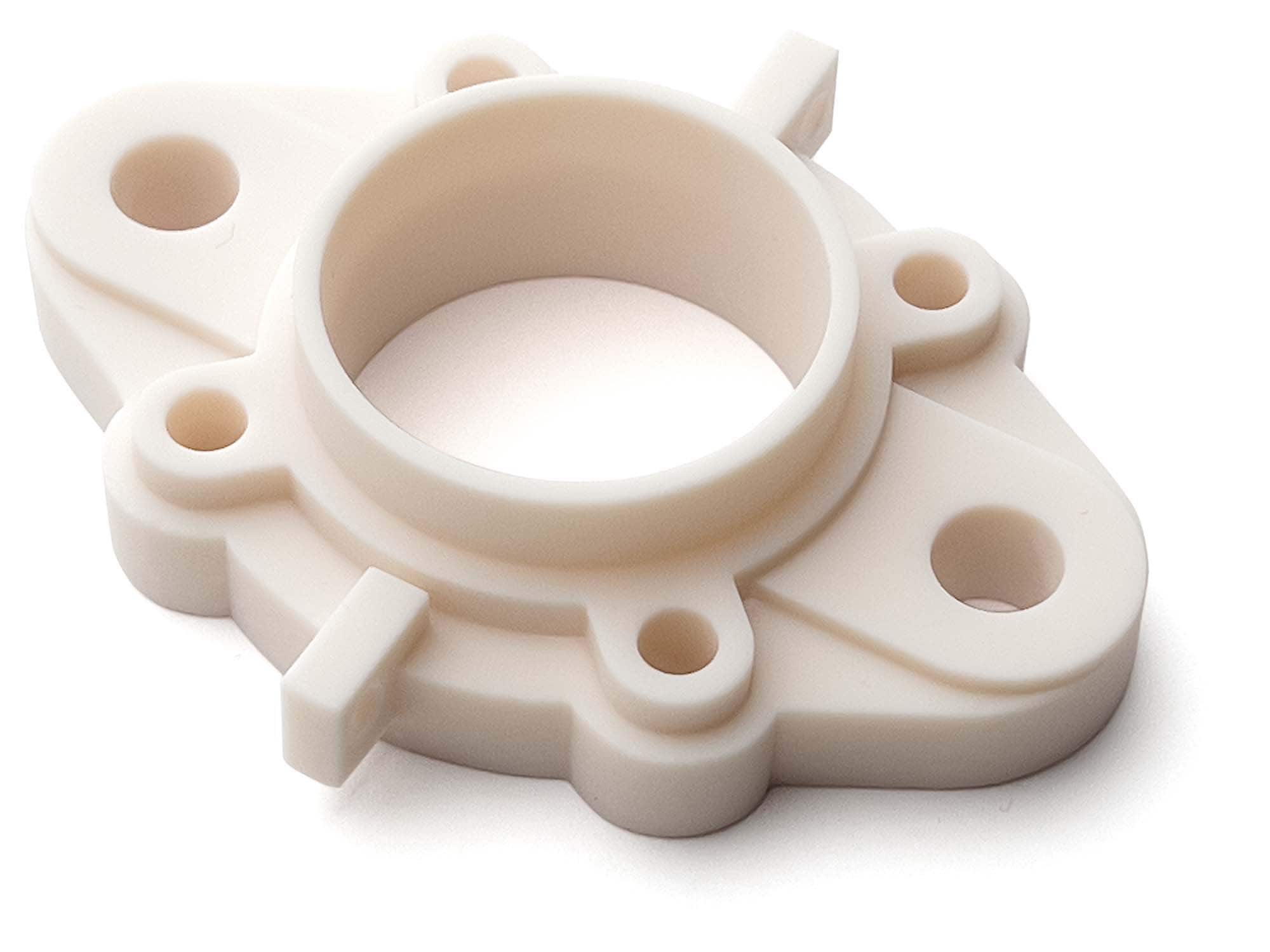

ceramic resin

Discover new possibilities for advanced 3D printing with Ceramic Resin - Experience the exceptional heat resistance, extreme rigidity and distinctive aesthetics of ceramic for a wide range of professional, industrial and technological applications.

PROS

- Ceramic-like look and finish

- Homogenous matt finish

- High elastic modulus

- High thermal resistance

CONS

- Low impact resistance

MAIN FEATURES

- 3D Printing process: MSLA

- Tolerances: ± 0,60mm < 100mm; ± 0,75% > 100mm

- Max size: 280 x 165 x 400 mm ; 11 x 6.5 x 15.7 in

- Lead time: <2 days

CERAMIC RESIN 3D PRINTED VIDEO GALLERY

LOOK AND FINISH

In addition to its mechanical properties, it offers a unique aesthetics reminiscent of traditional ceramics. This adds a quality touch to the moulded parts, making them not only functional, but also aesthetically pleasing.

HOMOGENEOUS MATT FINISH

Pieces moulded with this material have a smooth, uniform and matt surface finish. This aesthetic quality enhances the visual appeal of moulded parts, giving them an elegant, ceramic-like appearance.

HIGH THERMAL RESISTANCE

The material is designed to withstand high temperatures without compromising the structural integrity of the moulded parts. This makes it an ideal choice for applications such as electronic housings or wind tunnel test models, where the part may be exposed to high temperatures.

IMAGE GALLERY

INSTANT QUOTE FOR YOUR PARTS

free instant quoteCOMMENT

The new Ceramic Resin is an innovative addition to our range of 3D printing materials. Designed for high heat resistance and high elastic modulus, this composite white ceramic resin offers unique functional and aesthetic qualities.

Pros

• Ceramic look and feel

It aesthetically presents a unique, uniform matt finish that offers a ceramic-like look and feel. This adds a refined touch to any 3D printed piece, distinguishing it from those made from other materials.

• High Thermal Resistance

One of the main characteristics of this material is its impressive thermal resistance. Unlike many traditional 3D printing resins that may deform at high temperatures, ceramic resin maintains its structural integrity even under heat. This makes it the preferred material for applications such as electronic housings and enclosures, heat sinks and even wind tunnel test models.

• High Elastic Modulus

It has a high elastic modulus, which means it has a high resistance to deformation under load. Its rigidity exceeds most other materials used in 3D printing, making it ideal for applications requiring a robust and rigid material.

Cons

• High Density

Despite its several advantages, it has some limitations. One of these is its high density, resulting in heavier parts than those printed with other 3D printing materials. For projects where weight is a key factor, this could be a critical issue.

• Low Impact Resistance

High rigidity, although it is an advantage in some applications, results in lower resistance to sudden impacts compared to more ductile materials. For components that might be exposed to high impact forces, other materials might be more appropriate.

Comparison to other common materials

Standard resin:

Compared to standard resin, Ceramic Resin offers greater thermal resistance and stiffness, making it a more suitable choice for high-temperature applications and those requiring high rigidity. However, standard resin may be a more suitable choice for applications requiring higher impact resistance or a lighter material.

ABS (Acrylonitrile Butadiene Styrene):

ABS is known for its strength and impact resistance. However, compared to ABS, Ceramic Resin has a higher thermal resistance and rigidity, making it a better option for high-temperature applications or those requiring a more rigid material. ABS, with its higher impact resistance and lower density, may be a better choice for applications requiring these properties.

Nylon PA12

Compared to nylon, this resin offers greater rigidity and heat resistance. While nylon has higher impact resistance and lower density, Ceramic Resin may be a better choice for applications requiring a more rigid material or those involving high temperatures.

In conclusion, the material offers a number of unique advantages, including high thermal resistance, high rigidity and unique aesthetics. However, it has limitations, such as high density and lower impact resistance. However, its distinctive properties make it an excellent material for a wide range of applications, such as electronic housings, heat sinks and more. The right choice depends on the specific requirements of the given project.

Best applications:

The high thermal resistance and rigidity of Ceramic Resin make it the ideal choice for a range of applications. These include:

Heat-Resistant Applications

The thermal stability of Ceramic Resin makes it ideal for items that need to withstand high temperatures. Electronic housings, heat sinks and other components that interact with high heat can be well-produced with this resin.

Wind tunnel test models

The high rigidity of the resin, combined with its thermal resistance, provides the perfect characteristics for producing models for wind tunnel tests, where materials need to withstand not only aerodynamic forces but also potentially high temperatures.

Decorative and Household Items

Thanks to its unique ceramic-like aesthetics, Ceramic Resin can be used to create a range of decorative objects, from vases to statues, and even household items such as lighting devices or tableware.

Engineering Prototypes

For prototypes requiring high rigidity and thermal deflection, Ceramic Resin can provide a solution. Designers can validate their models in real-world conditions, making it a valuable tool in the design and testing process.

Conclusions

Briefly, Ceramic Resin solves a crucial gap in the 3D printing landscape. Although not the most suitable choice for all projects due to its higher density and lower impact resistance, its high thermal resistance, rigidity and unique aesthetics make it an exceptional choice for a wide range of applications.

Regardless of whether you are designing a heat-resistant part, creating a rigid model for the wind tunnel or crafting a beautiful object for the home, Ceramic Resin offers performance and aesthetic qualities that are hard to beat. As 3D printing expands and evolves, the field of application for this innovative material is set to grow.

"An engineering job with Ceramic Resin from Weerg turned out to be a wonder: it is the “Manhattan" of 3D printing materials! Durable, stylish and easy to work with. What about Weerg service? A Woody Allen film, full of twists and turns and always satisfying. Five stars all round!"

PROPERTIES

| Tensile breaking load | 76 MPa |

| Modulus of elasticity | 10000 MPa |

| Elongation at break | 1 % |

| Flexural modulus | 8780 MPa |

| HDT 0.45 MPa | 280°C |

| Izod impact resistance | 2,4 kJ/m² |

Questions and answers

Ceramic resin is a 3D printing material distinguished by its matte surface finish and its appearance similar to traditional ceramics. It is designed to combine the aesthetics of ceramics with the advanced performance of technical resins, offering an ideal solution for applications requiring high rigidity and thermal resistance. With its high elastic modulus, ceramic resin is particularly rigid, making it perfect for functional and engineering prototypes. This material is produced using MSLA (Masked Stereolithography Apparatus) printing technology, which allows for components with precise details and high-quality surfaces. However, it is important to note that ceramic resin has low impact resistance, which makes it unsuitable for applications requiring high toughness or resistance to dynamic stress.

Ceramic resin is recommended for applications that require a balance between aesthetics, dimensional precision, and mechanical resistance, thanks to its rigidity, thermal resistance, and matte finish similar to traditional ceramics. It is particularly suited for the production of decorative and household items, such as vases, sculptures, lamps, and furnishing accessories, where visual appeal and surface quality are crucial. Its high rigidity and ability to maintain dimensional stability also make it ideal for engineering prototypes and functional components that must withstand static loads. Thanks to its heat resistance, ceramic resin is suitable for applications exposed to high temperatures, such as wind tunnel test models used in aerodynamics and the automotive sector. In these applications, it is essential to simulate mechanical behaviours in critical thermal conditions while maintaining structural stability. The combination of thermal resistance and rigidity also allows for the creation of accurate and reliable components for functional tests and engineering analyses. In summary, ceramic resin is ideal for decorative items, high-temperature applications, aerodynamic test models, and engineering prototypes requiring precision, rigidity, and excellent aesthetic surface quality. Its versatility makes it an optimal solution for projects that require a rigid, high-performance material with a refined matte finish.

Yes, ceramic resin is heat resistant and exhibits significant thermal stability. According to technical data, ceramic resin has a heat deflection temperature (HDT) of 280 °C at 0.45 MPa and 132 °C at 1.8 MPa, values that make it suitable for applications requiring resistance to high temperatures. This feature makes it particularly suitable for static components or engineering prototypes that must maintain dimensional stability and structural integrity in high-temperature environments. However, it is important to note that while thermally stable, ceramic resin has low impact resistance and is not suitable for applications subjected to dynamic stresses or impacts.

QUOTE IN 1 SECOND WITHOUT COMMITMENT

DON'T WAIT: UPLOAD YOUR 3D FILE AND GET A QUOTE FOR YOUR PARTS NOW!

Upload your 3D file to get one step closer to manufacturing your parts.

free instant quote