2 min read

Stainless Steel 304 and 316: Comparison Between the Two Grades of Stainless Steel

Stainless steel is one of the most widely used materials in modern industry thanks to its corrosion resistance, durability, and versatility.Among the...

2 min read

![]() Weerg staff

:

Aug 23, 2021

Weerg staff

:

Aug 23, 2021

The arrival of 3D printing technologies and on-demand digital manufacturing has revolutionised product development, giving rise to the modern concept of Rapid Prototyping.

In the past, creating a prototype meant waiting 60–75 days and facing high costs.

Today, thanks to additive manufacturing, it is possible to obtain functional prototypes in 3–7 days, drastically reducing time, costs and development risks.

This updated 2025 guide explains everything you need to know about rapid prototyping:

Rapid prototyping includes a set of industrial technologies that allow the creation of a prototype directly from a 3D CAD file in extremely short timeframes.

The technologies are almost always additive, meaning they build the model layer by layer from raw material in the form of filament, resin or powder.

reduces lead times from 2–3 months to 3–7 days;

enables rapid iterations;

accelerates go-to-market;

reduces risks and development costs.

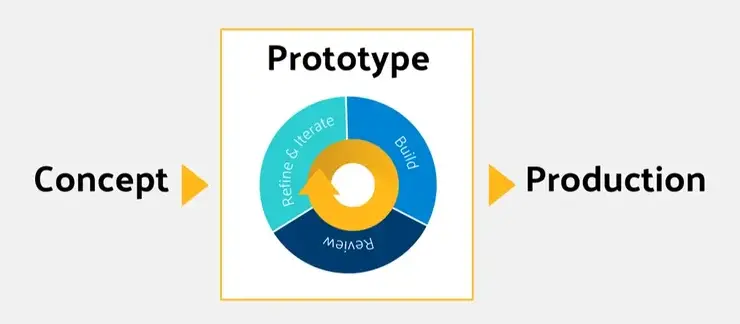

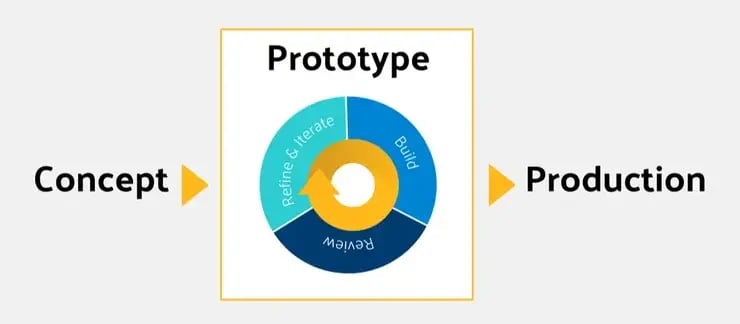

Prototyping is the phase in which a designer creates a physical model of their product to evaluate:

form

functionality

ergonomics

technical feasibility

component compatibility

The prototype is therefore the first real version of the project, useful for testing, modifications and validation before mass production.

| Method | Average lead time | Cost | Geometric complexity | Example technologies |

| Traditional prototyping | 60-75 days | High | Limited | Injection moulding |

| Rapid prototyping | 3-7 days | Low | High | MJF, FDM and MSLA 3D printing |

From months → to days.

Allows continuous iterations without slowing down the project.

A CNC or 3D-printed prototype costs a fraction of industrial tooling.

A digital model will never replace the physical perception of a real object.

It enables verification of:

ergonomics;

strength;

assemblies;

tolerances;

functionality;

mechanical performance.

Identifying a defect before production prevents thousands of pounds in wasted costs.

Used to evaluate:

shapes;

colours;

lines;

visual ergonomics.

Ideal technologies: SLA, MJF or high-resolution FDM.

Used to test:

loads;

strength;

movement;

assemblies;

tolerances;

real-world performance.

Ideal technologies: MJF, SLS, CNC, SLM/DMLS.

Used to confirm measurements, fittings and compatibility.

Exactly simulates the final product, including materials.

Rapid prototyping is cross-industry and is used in:

mechanics and automation;

automotive and motorsport;

eyewear and product design;

medical and biomedical;

electronics and consumer tech;

packaging and accessories.

It can be used in all phases of the production cycle:

concept and early design;

functional verification;

aesthetic mock-ups;

user testing;

events and presentations;

pre-production validation.

3D CAD design;

Selection of the most suitable technology;

Requirement analysis (aesthetic, functional, dimensional);

Rapid production (3D printing or CNC);

Post-processing (finishing, painting, treatments);

Testing and validation;

Iteration and improvement.

This cycle can be repeated several times until the perfect prototype is achieved.

reduce thicknesses → less material;

lighten solid parts → add cavities and relief holes;

reduce model size;

optimise orientation to reduce build volume;

choose the technology best suited to the required level of detail.

An online service like Weerg allows you to:

upload a 3D file and obtain an instant free quote

produce prototypes in a matter of hours

achieve industrial-grade quality with no investment in machinery

receive finished parts extremely quickly

It is the ideal solution for those who want to accelerate product development with professional tools.

Rapid prototyping is an essential ally for modern product designers.

It allows ideas to be tested, improved and refined in a short time while reducing risks and costs.

Whether you are developing a mechanical part, a functional component or an aesthetic product, rapid prototyping enables you to:

validate ideas

speed up the process

optimise the design

obtain real-world feedback

reach the market faster

2 min read

Stainless steel is one of the most widely used materials in modern industry thanks to its corrosion resistance, durability, and versatility.Among the...

2 min read

In the world of FDM (Fused Deposition Modelling) 3D printing, material selection is a key factor in determining the quality, functionality, and...

1 min read

Weerg, a global reference in additive manufacturing and online CNC machining, collaborates with CT Pack, an Italian leader in the design and...