4 min read

Uses of Metals: Types, Classifications and Applications

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

![]() Weerg staff

:

Jul 13, 2021

Weerg staff

:

Jul 13, 2021

If you are a professional who prints many parts in PA12/PA11 nylon or polypropylene PP with HP Multi Jet Fusion technology, nesting on 3D build can help you to obtain savings of up to 60%. How? Let's see it together.

Technologies like Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) print large "builds" filled with hundreds of items: since each build costs the same amount to print regardless of how many parts are inside, the more parts that can be squeezed into a single build the better the value of the build.

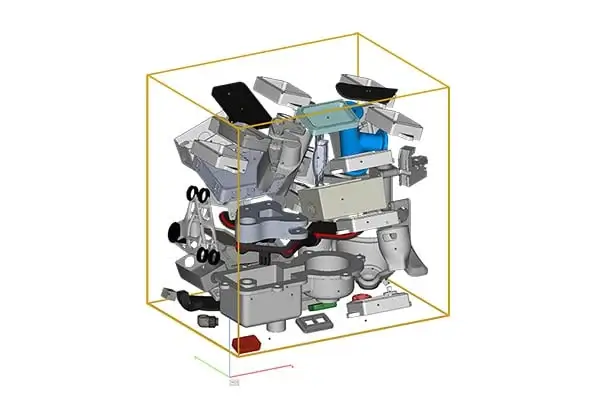

3D nesting in progress on the 3D build, still a lot of empty space to fill in this case.

Consequently, a 3D Nesting software translates and rotates automatically a collection of 3D parts inside the printing space (the 3D build) in order to minimize empty space and optimize the quality of the printed parts.

As it is easy to understand, even if it is possible to make builds of smaller dimensions, you can obtain top advantages from printing a 3D build only if you print enough parts to efficiently fill the build at is maximum size: if you are only printing a single part or a too small 3D build nesting will not be useful.

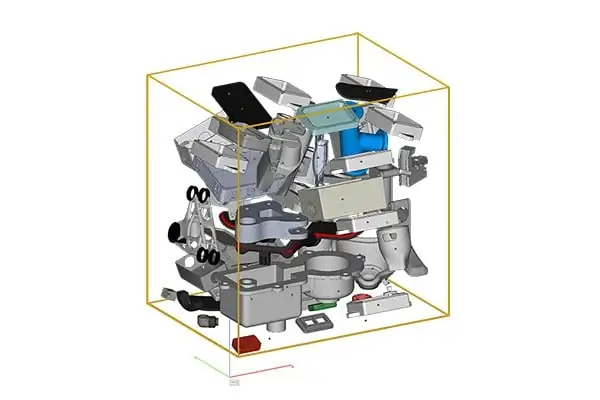

1. HP 5210 MJF 3D Printer, 2. Build unit, 3. Natural cooling station (it contains the 3D build), 4. Processing station

1. HP 5210 MJF 3D Printer, 2. Build unit, 3. Natural cooling station (it contains the 3D build), 4. Processing station

The 3D build nesting is easy because the guidelines are the same as for normal 3D printing, and any of the nesting software that we suggest below will automatically avoid interlocking and trapped parts. In fact, these are errors that can be made only with manual 3D nesting that we do not recommend.

You can get more informations and suggestions at this link.

Although there are many software with which you can carry out a manual nesting (for example you could use any 3D CAD software) we tend to not to recommend them because the optimization is too complex to be done properly and without errors by hand. This is why we recommend the following automatic software:

• Netfabb by Autodesk - instant free trial available

• Materialise Magics

• Fabpilot- instant free trial available

• Dimension 4 - instant free trial available

• 4D additive

• Polydevs

If you make hundreds of parts in nylon pa11, pa12 or polypropylene PP with MJF technology 3D build printing is essential because it not only allows you to make huge savings but also allows you to perfectly control the inclination and positioning of the parts according to their importance.

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...