In the world of industrial manufacturing and processing, selecting the right material is crucial to ensuring the quality, durability, and functionality of the final product. Among the most commonly used materials, PVC and aluminium are favourites due to their versatility and technical characteristics. But which of the two is the better choice for your needs? In this article, we explore the key differences between PVC and aluminium, analysing the advantages and disadvantages of both to help you make an informed decision.

PVC: Features and applications

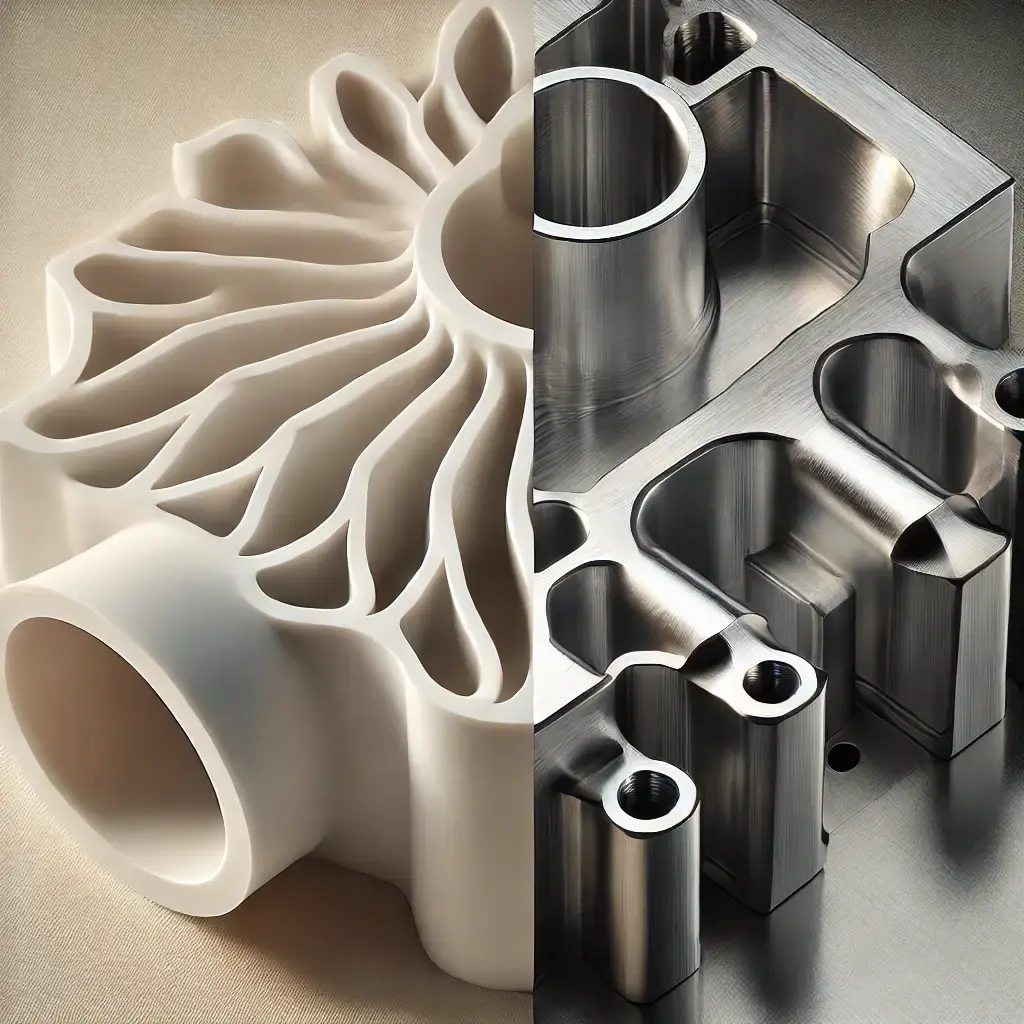

PVC (polyvinyl chloride) is a rigid, cost-effective, and versatile plastic, widely used in technical applications due to its high chemical resistance, excellent electrical insulation, and self-extinguishing properties. CNC machining of PVC allows for precise parts, particularly for industries like electronics or mechanics where weight reduction is necessary. PVC is easy to mill, turn, and drill with tight tolerances. However, it is less impact-resistant than metals and more sensitive to high temperatures. Thanks to its machinability, PVC is ideal for components that require medium to low mechanical stress or exposure to corrosive chemicals.

Advantages of PVC

- Lightweight: PVC is significantly lighter than aluminium, making it especially suitable for projects where reduced weight is a critical factor.

- Corrosion resistance: Unlike aluminium, PVC is not susceptible to corrosion, making it ideal for applications in humid or chemically aggressive environments, such as piping or window frames.

- Thermal and acoustic insulation: PVC is an excellent insulator, both thermally and acoustically. This makes it highly valued in the construction of windows, where energy efficiency and noise reduction are essential.

- Competitive cost: n terms of pricing, PVC tends to be more affordable than aluminium. For those seeking a cost-effective solution without sacrificing performance, PVC is an advantageous choice.

Disadvantages of PVC

- Lower mechanical strength: Although PVC is durable, it does not offer the same structural robustness as aluminium. It may deform or break under heavy loads or extreme conditions.

- UV sensitivity: Prolonged exposure to UV rays can cause PVC to deteriorate and discolour, making it less suitable for long-term outdoor use unless treated with stabilising additives.

Aluminium: light, strong and durable

Aluminium, on the other hand, offers a unique combination of lightness and mechanical strength. It is used in industries such as aerospace, automotive, and construction, thanks to its resistance to corrosion and wear. Commonly used aluminium alloys, such as 7075 and 5083, offer excellent CNC machinability, allowing for parts with tight tolerances and smooth surfaces. Aluminium can be milled, drilled, and turned with high precision. However, harder alloys like 7075 present challenges in welding and offer lower corrosion resistance compared to softer alloys like 5083.

Advantages of aluminium

- Mechanical strength: Aluminium provides significantly higher mechanical strength than PVC, making it ideal for applications requiring structural durability, such as frames, support structures, and components subject to high stress.

- Relative lightness: Although heavier than PVC, aluminium is one of the lightest available metals. It is, therefore, the preferred choice for projects requiring a balance between weight and strength, such as in the transport sector.

- Weather resistance: Aluminium is naturally resistant to weathering and does not rust. It is perfect for outdoor applications where durability, weather resistance, and longevity are required.

- Recyclability: Aluminium is highly recyclable without losing its original properties, making it a sustainable choice, particularly in an era where sustainability is a key factor in industrial decision-making.

Disadvantages of aluminium

- Poor thermal insulation: Compared to PVC, aluminium is a poor thermal and acoustic insulator. For this reason, it is often used in combination with other materials or fitted with thermal breaks to improve its energy performance.

- Higher cost: Aluminium tends to be more expensive than PVC, which can be a limiting factor for projects where budget constraints are significant.

Technical comparison

- Durability and strength: Aluminium is significantly stronger than PVC, both in terms of mechanical resistance and long-term durability. For components subject to high loads or wear, aluminium is the optimal choice.

- Weight: While both materials are lightweight compared to denser options such as steel or brass, PVC is even lighter, making it ideal for applications where further weight reduction is critical.

- Chemical and temperature resistance: PVC excels in corrosive environments and as an electrical insulator. Aluminium, on the other hand, is corrosion-resistant and better suited to withstand temperature changes, though it is less ideal for extremely high temperatures without protective coatings.

- Cost and accessibility: PVC is generally more affordable than aluminium. However, the cost of aluminium is justified when advanced structural properties are required.

The choice between PVC and aluminium largely depends on the specific application and project requirements.

- For applications requiring thermal or acoustic insulation, such as window frames for homes or offices, PVC might be the better choice. In addition to being economically advantageous, it offers good performance in terms of energy efficiency and comfort.

- For structural applications, where superior mechanical strength and durability are needed, aluminium is the clear winner. This applies to supporting structures, frames, and projects exposed to high stress or extreme weather conditions.

- Sustainability: If sustainability is a crucial aspect of the project, aluminium, with its high recyclability, may be more attractive. However, the lower energy impact of PVC production compared to many other materials, including aluminium, should also be considered.

- PVC: Due to its ease of machining, it is ideal for prototypes and small productions. Its plastic nature reduces tool wear and speeds up production times.

- Aluminium: While requiring more robust and precise tools, aluminium allows for high-performance components with excellent surface finishes, thanks to advanced CNC machining. Aluminium alloys can be machined with ISO precision tolerances (fine or medium class).

Conclusion

Both materials, PVC and aluminium, offer distinctive advantages and limitations depending on the application, required strength, weight, cost, and specific needs. In general, PVC is ideal for projects requiring insulation, chemical resistance, and cost-effectiveness, while aluminium is preferred in contexts demanding greater structural strength, durability, and sustainability.

At Weerg, we specialise in the production of components made from both materials and are here to help you find the most suitable solution for your manufacturing and production needs. With our advanced CNC technologies and industry expertise, we guarantee precision and quality for every project, regardless of the material chosen.

Contact us for more information or a personalised quote, and discover how we can support your business with innovative and tailored solutions.