6 min read

3D Printing and Nanotechnology

3D printing and nanotechnology are two fields of research and innovation that, at first glance, might appear worlds apart. The former focuses on...

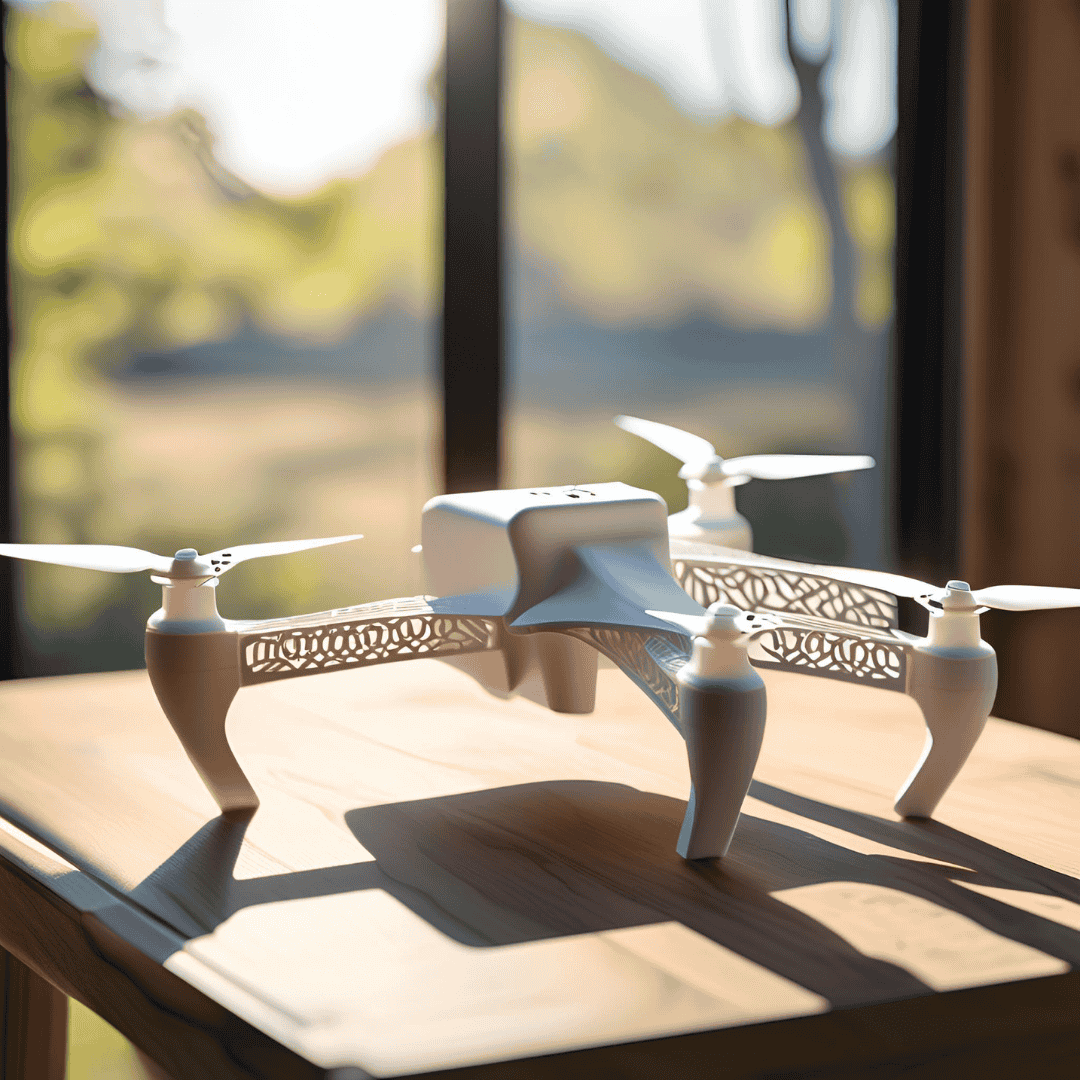

In recent years, drones have established themselves as one of the most innovative and versatile technologies, transforming sectors such as inspection, security, entertainment, logistics and even search and rescue. At the same time, 3D printing has accelerated drone development, offering new opportunities in terms of customisation, optimisation and cost reduction. In this article, we will explore how these two technologies are converging and what the future holds for the industry.

The drone market in Italy is experiencing consistent growth. By the end of 2023, it reached an estimated value of €145 million, marking a 23% increase compared to the pre-COVID period. This sector is primarily divided into two categories.

The first category, known as "Aerial Operations," accounts for over 90% of the market and consists of small to medium-sized drones. These devices are predominantly used for inspection, security, surveillance and research activities, finding applications in public administration, environmental protection and the entertainment sector, where they are employed in shows and media productions.

The second category, referred to as "Innovative Air Mobility and Delivery," is still in its early stages. This segment focuses on large drones designed for transporting goods and, to a lesser extent, people. A significant portion of activities in this sector revolves around the transport of medical supplies, which represents 67% of total applications.

3D printing is playing a pivotal role in drone innovation, particularly through Multi Jet Fusion (MJF) technology. This system enables the creation of highly customised and optimised drone components, whether structural, functional or aesthetic.

Commonly used materials include PA12 and PA11 nylon, ideal for structural parts that must withstand high mechanical loads, and TPU, which is excellent for components requiring flexibility and impact resistance. The ability to produce complex, lightweight shapes significantly enhances drone performance by improving aerodynamics and reducing overall weight.

Commonly used materials include PA12 and PA11 nylon, ideal for structural parts that must withstand high mechanical loads, and TPU, which is excellent for components requiring flexibility and impact resistance. The ability to produce complex, lightweight shapes significantly enhances drone performance by improving aerodynamics and reducing overall weight.

Beyond technical aspects, 3D printing is transforming the entire production chain. Technologies like Multi Jet Fusion (MJF) not only produce high-performance parts but also minimise material waste and reduce production costs. This represents a significant step towards more sustainable manufacturing, meeting market demands where speed and precision are essential. The ability to create prototypes or small production runs with the same efficiency as large-scale industrial processes makes 3D printing an indispensable technology for drone manufacturers.

One of the primary benefits of 3D printing for the drone industry is production scalability, enabling an effortless transition from a single prototype to mass production. This is especially advantageous for companies operating in research and development, where continuous design iteration is crucial for testing and improving performance. The ability to produce components quickly, regardless of quantity, accelerates the innovation process while maintaining cost control.

Multi Jet Fusion technology, widely used for drone component production, ensures consistent quality even for complex geometries. This allows companies to drastically reduce time-to-market—the time required to bring a product from concept to commercialisation. In a competitive market like that of drones, rapid innovation often translates into market leadership. Design changes that once took weeks of work and approvals can now be implemented in a matter of days by simply updating the digital project file.

Multi Jet Fusion technology, widely used for drone component production, ensures consistent quality even for complex geometries. This allows companies to drastically reduce time-to-market—the time required to bring a product from concept to commercialisation. In a competitive market like that of drones, rapid innovation often translates into market leadership. Design changes that once took weeks of work and approvals can now be implemented in a matter of days by simply updating the digital project file.

Another key benefit of 3D printing is the ability to create lighter components without sacrificing strength or durability. In drones, weight is a critical factor that affects autonomy, speed, and payload capacity. By reducing the weight of components through the use of advanced materials and advanced topological optimisation, more energy-efficient drones can be developed, capable of longer flights and superior performance. Finally, 3D printing enables the customisation of each component to meet specific client or application needs, opening new opportunities for drone manufacturers to deliver tailored solutions to rapidly evolving sectors such as transport, security, and logistics.

Designing a 3D-printed drone involves a structured and rigorous process. Initially, a conceptual design is developed, defining the drone's key characteristics, such as top speed and autonomy. Next comes aerodynamic optimisation, using structural analysis with the Finite Element Method (FEM) and Computational Fluid Dynamics (CFD) simulations. These steps are essential to ensure the drone’s stability and efficiency.

Once the design phase is complete, prototypes are created using 3D printing to conduct experimental testing and implement any necessary improvements. The final production phase involves a careful selection of materials and printing technologies based on the specific function of each component, whether aerodynamic or functional.

The applications of 3D-printed drones are vast and continually expanding. In the industrial sector, drones are used for the inspection and monitoring of infrastructure, such as bridges and power lines, ensuring greater safety and efficiency. In medical logistics, drones deliver biological samples and medications quickly and effectively, providing essential support in emergencies.

In the entertainment industry, 3D printing allows for the creation of unique and lightweight designs for drones used in shows and events. These drones enable the creation of extraordinary, fully customised visual effects, enhancing the audience’s experience.

With exponential growth predicted in the coming years, the drone industry in Italy is poised for further innovation. The integration of 3D printing promises to accelerate this evolution, making drones increasingly accessible, customisable, and high-performing.

In a world where speed, efficiency, and sustainability are top priorities, 3D-printed drones represent the future. Companies like Weerg, with their advanced 3D printing technology, are ready to support businesses and professionals in this technological revolution, offering bespoke solutions tailored to their needs.

6 min read

3D printing and nanotechnology are two fields of research and innovation that, at first glance, might appear worlds apart. The former focuses on...

6 min read

Padel has seen exponential growth in Italy and worldwide in recent years. A glance at sports clubs in major cities and smaller towns alike reveals an...

6 min read

The game of chess boasts a history spanning millennia, seamlessly merging art, strategy, and culture into a singular experience that has captivated...