6 min read

3D Printing and Nanotechnology

3D printing and nanotechnology are two fields of research and innovation that, at first glance, might appear worlds apart. The former focuses on...

Traveling back in time to Michelangelo’s day, there were no CNC online resources or the freedom to get a CNC instant quote online. The best tools that were available to use back then were a simple chisel and a hammer. Now, even though Michelangelo was able to create the iconic David statue with those said tools, they are surely not enough for today’s day and age to keep up with higher demands.

Jumping back into the present day, you have many more options you can take advantage of to fulfill your machining needs. And whether you are looking to develop a masterpiece like he did out of metal or plastics, or are seeking to raise the bar on the types of geometries that you can machine, then leveraging cutting edge 5-axis CNC machining equipment is the best way to go.

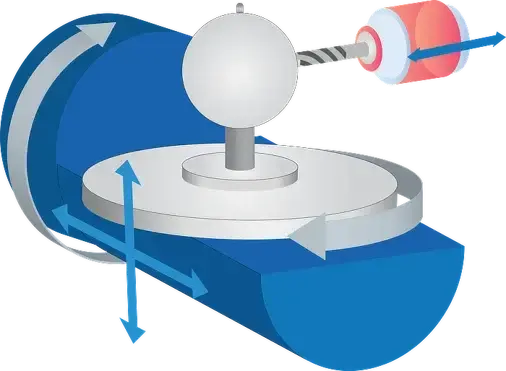

When talking about 5-axis machining, it is a more advanced technology over the traditional 3-axis version that has been utilized for decades. This particular model is able to move in five different directions, allowing machinists to have a desired five-sided approach for a single project. Most CNC manufacturers define their particular machine’s movements using the three primary axis points: X, Y, and Z (Z being the parallel to the tool spindle).

CNC machining in progress for a stainless steel part

CNC machining in progress for a stainless steel part

For reference, 3-axis can move a part in two directions (X and Y), whereas 5-axis can rotate due to the additional two rotary axes (A and B) to support the cutting approach from all directions. This means that where 5-axis CNC machining shines in its ability to create complex shapes within a single set up, which also reduces machinist’s labor time while increasing production rates.

Schematic representation of 5-axis machining

Schematic representation of 5-axis machining

Though we briefly covered it above, this section goes into a bit more detail on what the 5-axis in CNC actually entails. For starters, the 5 axes are paths that the tools or parts can move along simultaneously. The main ones are X, Y, and Y, and are a part of the basic Cartesian Coordinate System, which was first proposed by the well-known philosopher and mathematician, Rene Descartes, back in the 1500s. The three lines, aka axis points, intersect at a center point (the origin).

The last two axes, A and B, are a bit harder to visualize, as they rotate around the main X and Y ones. These additional points allow 5-axis CNC machining to reach advanced levels in operational streamlining over previous technologies to date.differences between the various types of CNC machining

There are tons of benefits with going with 5-axis CNC machining, with a key one being the fact that you now have more opportunity to create complex parts or designs that you once were not able to do before. No matter what the prototype is or how large it may be, you can accomplish it with 5-axis equipment while also saving time and money in the long run due to the greater precision abilities. Some other notable benefits you can expect to gain include:

If Michelangelo has access to 5-axis CNC machining or the internet to look up CNC online, then he could have pumped out hundreds, if not thousands of Renaissance masterpieces in record time. This device was built for speed, efficiency, accuracy, and diversity, and one that is undoubtedly a valuable asset today for those very reasons. And even though every manufacturing company has their own processes, more and more industries are taking advantage of 5-axis machining for its impressive benefits, making it a fundamental tool that will likely remain the preferred CNC machining method well into the future.

At Weerg we produce parts exclusively with 5-axis continuous CNC machines Hermle c42u and Mazak smooth.

Sources and further reading

https://www.5-axis.org/

https://www.engineering.com/AdvancedManufacturing/ArticleID/11930/The-What-Why-and-How-of-5-Axis-CNC-Machining.aspx

https://www.mazakusa.com/machines/process/5-axis/#:~:text=The%20term%20%E2%80%9C5%2Daxis%E2%80%9D,the%20workpiece%20from%20any%20direction.

https://blog.swantonweld.com/what-is-5-axis-cnc-machining

https://www.engineersedge.com/manufacturing/five-axis-cnc-machining.htm

6 min read

3D printing and nanotechnology are two fields of research and innovation that, at first glance, might appear worlds apart. The former focuses on...

6 min read

Padel has seen exponential growth in Italy and worldwide in recent years. A glance at sports clubs in major cities and smaller towns alike reveals an...

6 min read

The game of chess boasts a history spanning millennia, seamlessly merging art, strategy, and culture into a singular experience that has captivated...